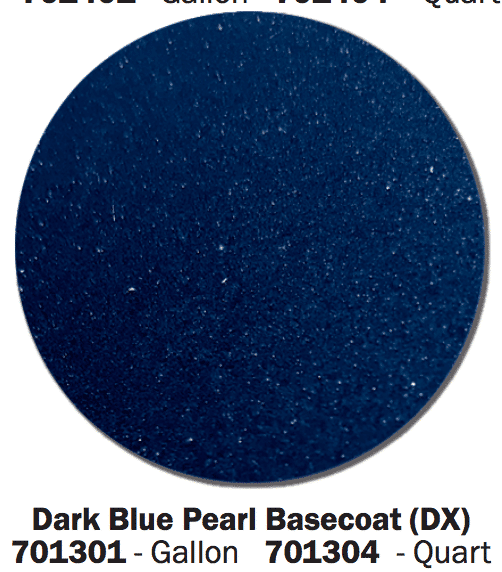

Dark Blue Pearl Base Coat 2 Quart or 2 Gallon Kit

$79.99 – $174.99

2 Quart Kit – 1 quart of basecoat color, 1 quart of Reducer

2 Gallon Kit – 1 Gallon of basecoat color, 1 gallon of Reducer

Excel Dark Blue Pearl Base Coat Series is a quick dry, good hiding, factory pack line of many popular colors. Various OEM colors are available. Ideal for overalls, large blend are repairs, or for ground-coat material.

| Reducer Drying Speed | Fast, Medium, Slow |

|---|---|

| Amount | 2 QUART KIT, 2 GALLON KIT |

Only logged in customers who have purchased this product may leave a review.

<

Excel Dark Blue Pearl Base Coat

DOES NOT SHIP OVERSEAS OR TO CALIFORNIA

This is a quick-dry, good-hiding, factory pack line of many popular colors. Various OEM colors are available. Ideal for overalls, large blend area repairs, or for ground-coat material.

For a complete and current list of colors offered, please visit www.excelproducts.net.

Application

Surface Preparation

For dry sanding, a final sanding step of P500-P600 grit is recommended using a maximum 100-grit step difference or less throughout the taken sanding steps.

For wet sanding, a final sanding step of P800-P1000 grit is recommended using a maximum of 200-grit step difference or less throughout the sanding steps.

Clean the area with a good-grade wax and grease remover such as #91001 and wipe dry with a clean cloth. Wipe the area with a tack cloth to remove any dust or dirt particles.

Mixing Directions

- 2 Parts Excel Basecoat

- 1 Part Excel Urethane Reducer

Spray Gun Set-up

- Compliant Gravity feed: 1.3-1.5mm, 30 PSI at the spray gun air inlet

- Gravity feed HVLP: 1.3-1.5mm, 10 PSI max at air cap

- Siphon feed: 1.6-1.8mm, 40-50 PSI

Application

Apply 2 – 4 single coats or until full coverage is achieved.

Drying Schedule

Allow each coat to flash off for approximately 5 to 10 minutes at 70°F.

Prior to clear coat application, allow a minimum of 20 minutes flash time at 70°F and a maximum of 24 hours flash time at 70°F.

If the maximum time is exceeded, scuff the surface and apply another coat.

Cleaning of Equipment

Clean equipment with lacquer thinner.

Technical Data

- Mixing Ratio: 2:1 by volume w/reducer

- Pot life: Indefinite, if not catalyzed

- Viscosity @ Gun: 13 – 15 sec #4 Zahn

- Recommended Film Thickness: Approx. 0.4 – 0.8 mil

- Flash Point: 53°F TCC

- Air Pressure @ Gun: 30 PSI gravity feed, 10 PSI max at cap HVLP, 40-50 PSI siphon feed

- Coverage @ 0.6 mil: 286 sq ft/g

- VOC @ Gun: Maximum of 6.8 lb/gal in ready-to-spray form

Table of Contents

Reviews